The Core Components of a Lighting Fixture

Luminaires are not simply a combination of "light source + housing," but rather a sophisticated system integrating optical design, mechanical structure, electrical safety, and thermal management technology. The rationality of its components directly determines the lighting effect, service life, safety performance, and user experience. Whether it's a household ceiling light, a commercial spotlight, or an outdoor floodlight, despite their varied forms, their core components are highly consistent.

XINSANXING will dissect the seven core components of luminaires from a professional perspective, combining industry standards and technical details to help you comprehensively understand luminaire structure.

I. Light Source and Mounting Interface

The light source is the core light-emitting component of a luminaire, while the mounting interface is responsible for the installation, positioning, and electrical connection of the light source. Together, they form the basic functional unit of the luminaire.

1. Light Source Types

Traditional light sources: Incandescent lamps, fluorescent tubes (require ballast for starting).

LED light sources: SMD LED (surface-mount), COB LED (integrated), accounting for over 90% of the modern lighting market, featuring energy efficiency and long lifespan.

Special light sources: Halogen lamps, high-pressure sodium lamps (industrial/outdoor applications).

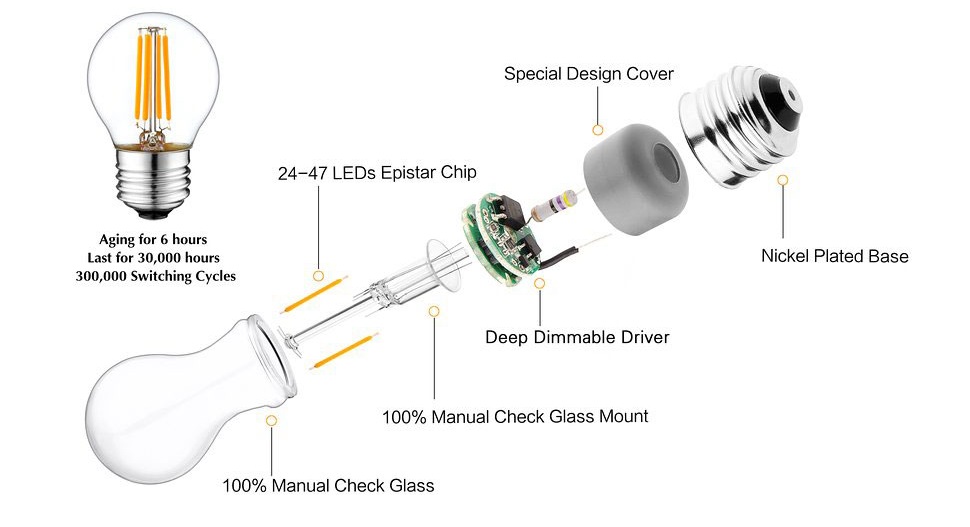

2. Mounting Interface Components

Lamp holder/socket: Standardized design (E27/E14 screw type, GU10/G13 plug-in type), ensuring stable installation of the light source and current conduction.

Positioning mechanism: Card slots, brackets, etc., ensuring the relative positional accuracy between the light source and optical components (lenses/reflectors), directly affecting the beam control effect.

Electrical connectors: Terminal blocks, quick connectors, which must meet insulation level and conductive stability requirements.

II. Optical System

The optical system is a key module that controls the light propagation path and optimizes lighting effects. Its core objectives are to improve luminous efficiency, prevent glare, and achieve precise light distribution.

1. Core Optical Components

1.1 Reflector:

Material: Anodized aluminum, high-reflectivity plastic. Surface treatments include mirror (concentrating), frosted (diffusing), and orange peel texture (anti-glare) types.

Shape: Parabolic (spotlight focusing), elliptical (uniform light distribution), polyhedral (large-area illumination)

1.2 Lens / Lens Group:

Material: PC (impact resistant), PMMA (high light transmittance), glass (high temperature resistant)

Type: Convex lens (focusing), concave lens (diffusing), Fresnel lens (lightweight and efficient), TIR lens (total internal reflection, luminous efficiency up to 95%)

Diffuser/Cover: Opaque PC, frosted glass. Through haze design (30%-80%), the light is made uniform and soft, eliminating the harshness of point light sources.

Shading Components: Grilles, honeycomb mesh. Deep shading design can control the glare value (UGR) below 19, suitable for offices, classrooms, and other scenarios.

2. Optical Cavity

A closed space that houses the optical components. The inner wall is usually coated with a high-reflectivity coating (reflectivity ≥90%) to reduce light loss.

III. Mechanical Frame and Housing

The mechanical structure is responsible for supporting and protecting the internal components, while also determining the luminaire's appearance and installation method. It must balance strength, protection, and aesthetics.

1. Core Structural Components

Main Frame: Material selection depends on the application scenario.

Metal materials: Aluminum profiles, die-cast aluminum (good heat dissipation, suitable for LED luminaires), stainless steel (corrosion resistance for outdoor use).

Plastic materials: ABS, PC (lightweight, low cost, suitable for indoor luminaires).

Cover/Lens: A protective layer covering the optical components, also serving a decorative function. Common types include glass covers (crystal lamps) and metal mesh covers (industrial-style luminaires).

Sealing Structure: Waterproof rubber rings, sealants, and labyrinth designs are used to achieve IP protection ratings (IP44 dustproof and waterproof, IP67 for underwater use), and are essential components for outdoor luminaires.

Indoor Installation Interfaces: Hanging rings (pendent lights), ceiling plates (ceiling lights), embedded frames (downlights).

Outdoor Installation Interfaces: Pole-mounted brackets, wall-mounted brackets, tripod interfaces.

2. Convenient Installation Design

Quick-release structure: Spring clips (embedded downlights), magnetic connections (tool-free installation), solving the problem of cumbersome traditional installation.

Folding components: Extendable and rotatable rod structures, facilitating light source replacement and angle adjustment, reducing the risk of working at heights.

IV. Electrical and Electronic Components

The electrical system is responsible for power supply, control, and protection, directly impacting the safe operation and functional expansion of the luminaire. It must comply with international safety standards such as IEC/EN and UL.

1. Core Electrical Components

Driver Power Supply: Converts mains power to the appropriate voltage for the light source (LED luminaires require constant current drive), with built-in overload, overvoltage, and short-circuit protection functions, and an efficiency typically ≥85%.

Electrical Compartment: An independently sealed space that isolates the power supply from the optical components, preventing heat transfer and electrical faults.

Wiring Terminals/Junction Box: The connection point for external power lines, requiring clear labeling (Live wire L, Neutral wire N, Ground wire PE), and insulation resistance ≥2MΩ.

Control Module:

Basic Control: Switches, dimming knob (0-10V dimming).

Smart Control: Wireless modules (Bluetooth, WiFi), human body sensors, light sensors (for automatic switching/brightness adjustment).

2. Safety Design Highlights

Flame-retardant Materials: The electrical compartment casing must meet V0 flame-retardant standards.

Insulation Isolation: The distance between live parts and the metal casing must be ≥3mm (IEC standard).

EMC Electromagnetic Compatibility: Reduces electromagnetic radiation interference and meets Class B requirements.

V. Cooling System

Only 30% of the electrical energy in an LED light source is converted into light energy; the remaining 70% is converted into heat. Poor heat dissipation leads to accelerated light decay and shortened lifespan of the light source. Therefore, the cooling system is a core technical module of LED lighting fixtures.

1. Core Cooling Components

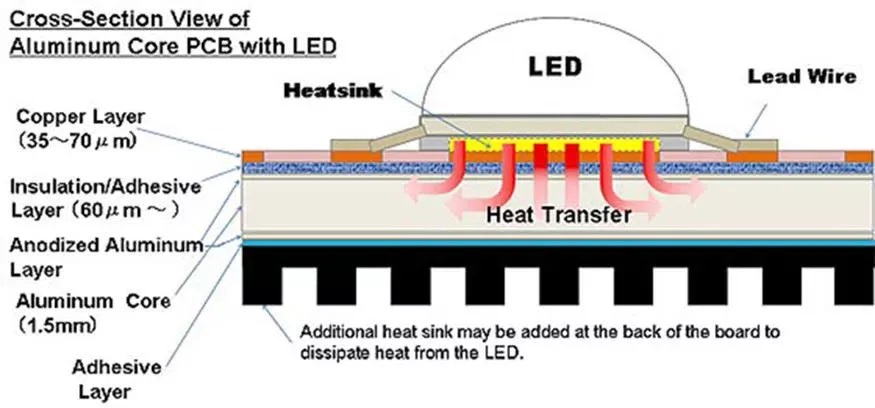

Heat Sink:

Types: Aluminum extruded profiles (low cost), die-cast fins (efficient heat dissipation), heat pipes (high-power lighting fixtures)

Design Key: Fin area (≥5cm² of heat dissipation area required per 1W of power), spacing (≥3mm, to ensure air circulation)

Thermal Interface Material: Thermal grease (thermal conductivity ≥1.5W/m・K), thermal pads, filling the gap between the light source substrate and the heat sink to reduce thermal resistance

Cooling Methods:

Natural Convection: Utilizing the principle of hot air rising through the design of the casing fins (suitable for ≤50W lighting fixtures)

Forced Air Cooling: Built-in miniature fan + air duct (suitable for ≥100W high-power lighting fixtures)

2. Heat Dissipation Path Design

Heat Source (LED chip) → Thermal Interface Material → Heat Sink → Natural Convection / Forced Air Cooling → Environment, the total thermal resistance needs to be controlled at ≤5℃/W

VI. Adjustment and Control Mechanisms

This module enables flexible adjustment of beam direction, illumination angle, or brightness, enhancing the versatility and user experience of the lighting fixture.

1. Mechanical Adjustment Components

Rotation/Tilt Joint: A universal joint with a locking mechanism allows the fixture to be adjusted horizontally (360°) and vertically (0-90°), commonly found in spotlights and track lights.

Sliding Rail/Telescopic Structure: Adjusts the suspension height of the fixture (pendent lights) or the illumination distance (floor lamps).

Focusing Mechanism: Adjusts the spot size by changing the distance between the light source and the lens (professional photography lights, stage lights).

2. Brightness Control Methods

Physical Dimming: Knobs, levers (changing the current).

Smart Dimming: APP remote control, voice commands (requires a smart control module).

Scene Modes: Preset brightness schemes (e.g., reading mode, sleep mode).

VII. Installation and Maintenance Interface

A well-designed installation and maintenance system reduces construction difficulty and long-term operating costs, and is a crucial aspect of a lighting product's competitiveness.

1. Installation Assistance Components

Maintenance openings/covers: Openable faceplates and pull-out modules facilitate light source replacement and optical component cleaning.

Identification system: Clearly marked light source model, maximum power, installation steps, and electrical parameters (e.g., "Max 60W," "IP65").

Tool compatibility: Design includes sufficient space for manual operation, allowing installation without special tools.

2. User-Friendly Design Examples

Magnetic detachment: Quick magnetic disconnection through magnetic isolation components solves the problem of difficult detachment in traditional magnetic lighting fixtures.

Extendable components: Foldable rods can extend 1-2 meters downwards, allowing for light source replacement in high-mounted fixtures without the need for ladders.

Summary: Core Design Principles of Lighting Fixtures

The components of lighting fixtures must revolve around three core principles: "functional realization, safety and reliability, and optimized user experience":

Material Selection: Balancing heat dissipation, strength, cost, and weather resistance.

Structural Design: Meeting safety standards (electrical isolation, flame retardancy, protection rating).

Function Adaptation: Optimizing optical distribution and installation methods based on the usage scenario.

Whether you are a lighting designer, a professional in the decoration industry, or an ordinary consumer, understanding the principles of lighting fixture components will help you choose products more accurately and solve usage problems.

Post time: Jan-05-2026